What if you needed a kidney transplant and doctors could simply 3D print one for you? Such bioartificial organs aren’t available yet, but research is heading that way. Many 3D-printing technologies are already in use, creating everything from artificial coral reefs to custom prosthetics and even entire homes. Medicine is the next frontier.

Bioprinting uses 3D printers and bioinks that mix living cells with biopolymers. It can produce bioartificial skin to treat burns; bone and cartilage to repair fractures; nerves, tendons and vascular tissue; implantable valves; and rudimentary organs.

This tech is the basis of regenerative medicine, a healthcare approach that restores or replaces tissue or organs that have been damaged or have congenital problems instead of only treating symptoms.

Regenerative medicine could transform lives.

Disease in a dish

Now, researchers can work with actual human tissue instead of so-called animal models. Results of experiments can more closely match what happens in the human body.

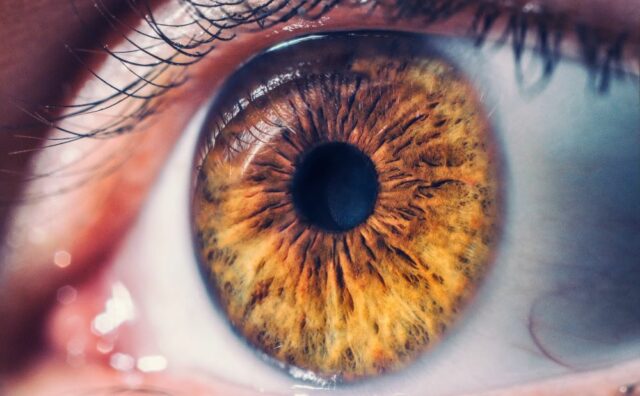

Researchers at the National Eye Institute used skin cells from patients and bioprinting to produce eye tissue to study degenerative retinal diseases such as age-related macular degeneration (AMD).

Lead author Dr. Kapil Bharti, senior investigator at the Ocular and Stem Cell Translational Research Section of the National Eye Institute, says this represents a step forward from using animals to conduct AMD research.

He says, “We have been able to recreate not only the biology of the tissues but also how the disease initiates and progresses. In my mind, this is a huge step forward in recreating human disease in a dish.

The process starts with producing three specialized types of eye cells from induced pluripotent stem cells. These are harvested from a person’s blood or skin and “reprogrammed” so they can be nudged into a variety of specific cell types.

These eye cells are printed onto a biodegradable polymer scaffold and placed in a growth medium. As the cells grow and divide, they form a network of blood vessels and reproduce the structure of the human eye where macular degeneration takes place.

It took the scientists two years to get the right mix of cells and hydrogel to use in the bioprinter. (Bharti says the right consistency is like soft toothpaste.) They also had to figure out how to freeze the cells so they’d be available when it was time to print—and to be able to do all this reliably.

This process can provide all the tissue researchers need to study degenerative eye diseases, but that’s only the beginning, according to Bharti. They could possibly grow healthy eye cells from a patient’s own blood or skin cells and then transplant them back, relieving or even curing the degeneration.

Lab-grown human eye structures have more potential for research, according to Bharti. “Another aspect of our research is trying to miniaturize and make mass production of these tissues, so we can do drug discovery, drug testing and drug toxicity, and try to connect that to differences in human genetics, so we can explore how drugs work or how drugs cause toxicity differentially in different people,” he says.

Animal-free drug testing

The ability to test drugs on actual human tissue instead of animals could revolutionize the pharmaceutical industry, where the probability of success of a new drug making it through clinical trials is a scant 5% to 26%.

For example, Penn State researcher Madhuri Dey is using 3D bioprinting to construct cancerous tumors. Her bioprinted breast-cancer tumor provided a microenvironment to test various treatments for a specific patient.

Because researchers and clinicians can use bioprinting technology to grow tissue or organs from an individual’s own pluripotent skin cells, treatments or medications can be tailored exactly to that person.

A new law, the FDA Modernization Act 2.0, eliminates the requirement that pharmaceutical companies must test drugs on animals before moving to human clinical trials—although they still can choose to test on animals. Instead, they can use groups of cells—the disease in a dish—or computer models. The bill, proposed by Senator Rand Paul, was signed into law in December 2022.

The bioprinting ecosystem

For bioprinting, you need the printer itself, a scaffolding material to print onto, and an ink that typically incorporates cells into a hydrogel material. The scaffold itself is often bioprinted. Because the field is so new, researchers often have to invent equipment or materials in order to further their work.

Amir Sheikhi, a Penn State assistant professor of chemical engineering, announced that his lab developed a new, granular hydrogel bioink that lets them print thicker material.

Hydrogels used for bioprinting aim to mimic the extracellular matrix that provides the environment for cells in the human body, according to Sheikhi. But these hydrogels have pores sized at the micron level, while the human extracellular matrix has micron-level pores.

“We’re now trying to make tissue-like constructs with these bioinks. We envision we can generate tissue-specific bioink for muscle, skin or bone.”

—Amir Sheikhi, assistant professor of chemical engineering, Penn State

So, when conventional bioink becomes thick during the printing process, nutrients can’t penetrate deeply into it, and cells die.

Sheikhi’s toothpaste-consistency granular bioink flows through the printer while maintaining optimum spaces between cells so that nutrients can flow through the medium.

This granular bioink is one of the building blocks of the major goals of the lab, which focuses on micro- and nano-engineering of soft materials for medical and environmental applications, according to Sheikhi.

“We’re now trying to make tissue-like constructs with these bioinks,” he says. “We envision we can generate tissue-specific bioink for muscle, skin or bone.”

A market for tools and supplies

There are several companies that now offer some or all the tools for bioprinting: bioinks, printers and accessories, and software. There are also service providers who will handle the full bioprinting process.

Research firm Market Research Future says the bioprinting industry as a whole will grow from $1.6 billion in 2021 to $5.1 billion by 2030. This will be fueled in part by medical advances that let clinicians save lives.

The global organ transplantation market was already estimated at $12.95 billion in 2021. In 1999, scientists at Wake Forest Institute of Regenerative Medicine transplanted the first engineered bladders into seven kids born with spina bifida. In 2003, they were the first to create a functioning solid kidney.

The consensus estimate of when 3D-printed organs will become commonly available is around 10 years from now. But before then, we’ll see implants of bioprinted tissue of all kinds—skin, blood vessels, valves, ligaments and tendons.

Long live the new flesh.

Lead photo courtesy of Shutterstock