By Nick Abbatiello, Sr. Distinguished Engineer in Sustainable Materials & Circularity, and Allison Ward, Senior Sustainable Materials Engineer, Dell Technologies

It’s one of those problems that will only be solved with creative thinking—and no compromises.

Electronic waste—“e-waste,” for short—is something we know a lot about from our work on sustainable materials at Dell Technologies. A big part of our job involves finding new ways to minimize this waste as much as possible.

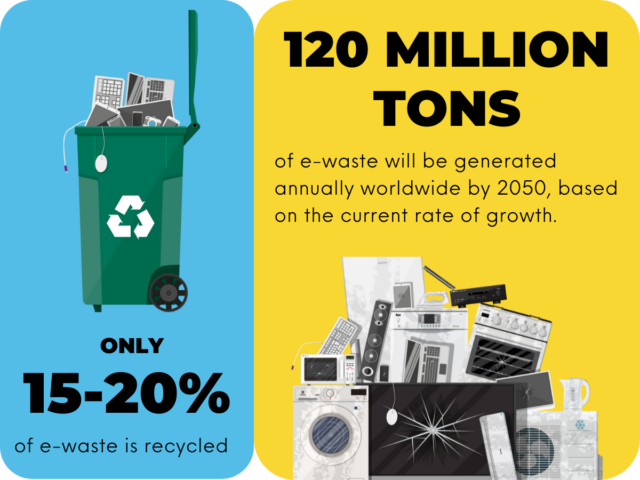

That probably sounds simple enough, but consider what the challenge actually entails. One estimate from the World Electrical and Electronic Equipment (or WEEE) Forum pegs the amount of electronic waste that ends up in the trash every year at more than 63 million tons worldwide. Pound for pound, the WEEE Forum notes, the amount of e-waste generated annually—a figure that includes everything from laptop computers to microwaves and mobile phones—is heavier than the Great Wall of China.

Furthermore, the Belgium-based organization reports that all signs indicate the situation will worsen in the years ahead. Due to short product lifecycles and a lack of repair options for equipment that breaks down, the generation of e-waste is growing by 3 to 4 percent per year. By 2030, the WEEE Forum predicts, the global total for tossed electronic waste will likely top 81 million tons.

From Dell’s perspective, as a company that builds computers, numbers like these are entirely unacceptable. The way we see it, it’s up to us to do everything we can to keep our finished products out of landfills and design them with sustainability in mind. Here’s a look at what we’re doing in this regard and some thoughts on how we plan to improve our e-waste reduction efforts moving forward.

Reuse and recycle

Let’s start at the moment an electronic device is no longer wanted by its original user. Maybe it’s reached the end of its functional life, or the customer is just ready for something new.

Either way, when a device comes back to us (we collect products made by any brand, not just Dell), we first give it a close inspection to see if it can still be used. If it’s in good shape or only requires a minor fix, we’ll typically resell it or donate it to a program that can hand it off to someone who needs it.

On the other hand, if the product can’t be repaired, we may decide to take it apart. Sometimes viable components can be repurposed for use in other devices—a process known as “closed-loop recycling.” The rare-earth magnets from the hard drive, such as plastic from a laptop’s casing or the parts of a broken monitor, might eventually wind up in an entirely new computer.

Complementing our closed-loop efforts are the “open-loop recycling” materials we get from manufacturers in other industries. Recycled plastics from around the world, for instance, are used to create our product packaging; and scrap carbon fiber from the automotive and aerospace industries is used to make components like computer LCD covers.

Less waste—by design

While repairing and reusing and all means of recycling are all critical to cutting e-waste, these efforts would have limited impact if we didn’t layin the groundwork for their success. For example, imagine if the laptops we made were all but impossible to take apart. And who would choose to recycle their computer if it was prohibitively expensive?

To head off potential issues like these, two other important aspects of our work are in the seemingly unrelated areas of design and customer service. First, on the product-creation front, we always strive to “design for repair“: We want our computers to be physically easy to fix, with parts that are easily accessible, replaceable and reusable.

Likewise, in the realm of customer service, we try to make the recycling process simple. Individual PC and laptop owners can drop off their old devices at participating Goodwill locations, and we’ll pick them up for recycling for free, or they can return these products themselves using our free mail-back program. It’s a similar story for our business customers who get their devices through our APEX “as-a-service” subscription models: When you no longer need a certain technology, we just take it back and recycle, reuse or repurpose it on your behalf.

Other environmental considerations also factor into our e-waste calculations, of course. For instance, can we justify shipping components halfway across the world just to recycle them? Do we want a recycled part produced in a coal-powered smelting factory? Should we instead procure that component elsewhere—like the hydro-powered smelter down the road?

The bottom line is, when it comes to e-waste, we want to be sure that any action does more for the planet than it takes away. Determining if that’s the case isn’t always straightforward, but we know it’s always the right thing to do.

For a different take on redirecting e-waste, check out this article about an artist who’s using his talents to bring attention to the issue.

Graphic sources: U.S. PIRG, Circular Electronics Partnership