With the summer time in full swing, most of us are thinking about vacation, beaches, and finding ways to escape on our next adventure. My idea of an adventure is embedding myself in nature by going on a nice long bike ride.

It’s important to spend time with nature to remind us of its beauty, fragility and our responsibility to protect it. Advancing sustainability is a key focus for our 2030 vision. We have a responsibility to protect and enrich our planet together with our customers, suppliers and communities, and to embed sustainability and ethical practices into all that we do.

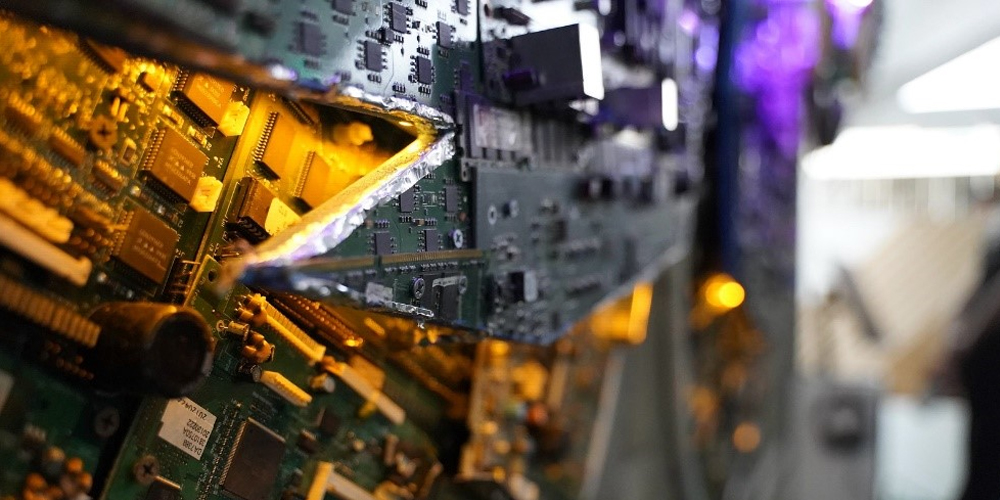

Addressing the fastest growing domestic waste stream

For our part, we are focused on addressing the growing challenge of electronic waste. For those not familiar, e-waste is one of the fastest growing waste streams on the planet. Estimates show approximately 50 million tons of e-waste is generated worldwide, but only 29% of it is recycled properly. Unfortunately, the other 71% is typically stockpiled in household garages, handled informally, or thrown into the landfill.

We do our part to enable our customers to recycle responsibly, and this time last year, we shared news about a new partnership with the Basel Action Network (BAN) introducing an asset tracking pilot program to use technology utilized by BAN to provide greater transparency into our own US electronics recycling programs.

1 year later: What have we learned?

Well, for starters, we learned GPS-based asset tracking works, and we learned that the majority of our downstream recycling processes are operating as we expect. But the pilot program did expose some early vulnerabilities which helped us quickly take corrective action and addresses the operational gap.

Additionally, the pilot has led to us making global tracking technologies part of Dell’s existing electronics disposition partner audit program. As I just shared, e-waste is a significant issue. The numbers above justify how we need more innovative solutions to meet the increasing challenge of recycling electronics. BANS’s e-waste tracking service is one way we are tackling the problem.

Ensuring responsible recycling is only one piece of solving this problem.

The bigger opportunity is to think circular from the very beginning and remove waste from the entire process. When waste becomes a design principle and an input into our manufacturing process, e-waste goes away. The most recent example of this is a collaboration with suppliers Seagate and Teleplan (a storage device recycling/recovery specialist). Together we’ve created a new closed-loop process to recover the rare earth magnets from recovered enterprise equipment. The magnets are then reformed for reuse in new hard-disk drives – most notably the Dell Latitude 500 series laptop. Not only is this a winning example of circular economy, but it’s finding ways to reuse rare earth metals, which have serious environmental and health consequences if not properly managed.

As we embrace a new 2030 vision: Progress Made Real, our success will be dependent on new business models and new ways of partnering with customers, suppliers, manufacturers, or NGOs. This is where the innovation happens and how we will get the scale to make progress real.